Slot time is a concept in computer networking. It is at least twice the time it takes for an electronic pulse (OSILayer 1 - Physical) to travel the length of the maximum theoretical distance between two nodes. In CSMA/CD networks such as Ethernet, the slot time is an upper limit on the acquisition of the medium, a limit on the length of a packet fragment generated by a collision, and the scheduling quantum for retransmission.[1]

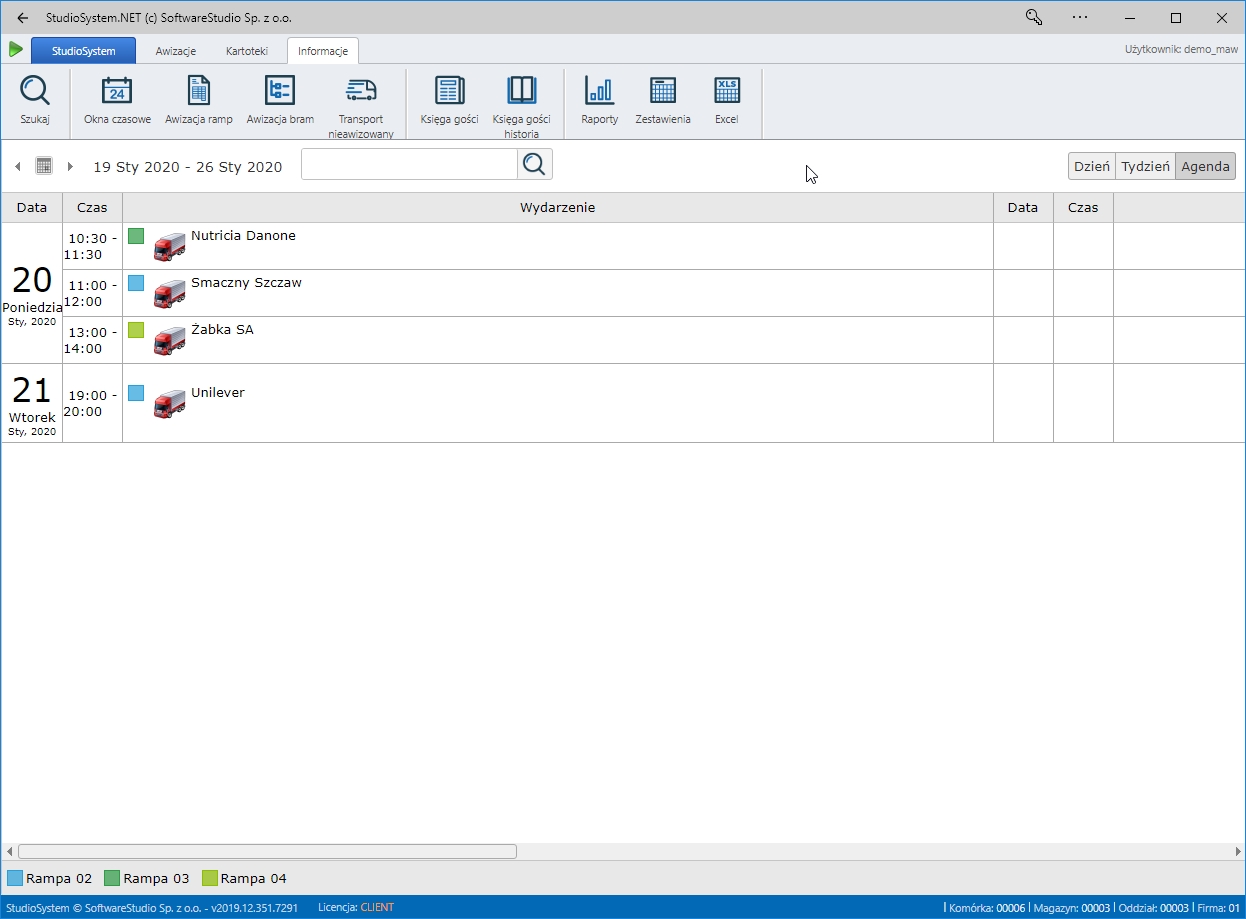

Time management for basketball coaches doesn’t stop when practice ends and the players go home. If you are lucky enough to offer additional private practice sessions, work for a club or work exclusively as a private coach/trainer you know this struggle all too well. Some time slot management systems set a sequence for loading and unloading from booked time frames and truck arrival times – this relieves entry gate and dock-side personnel from handling this task.

Since a pulse's runtime will never exceed slot time (the maximum theoretical time for a frame to travel a network), the network interface controller, or NIC waits a minimum of slot time before retransmitting after a collision happened, in order to allow any pulse that was initiated at the time that the waiting NIC was requested to send, to reach all other nodes. By allowing the pulse to reach the waiting NIC, a local collision occurs (i.e. while still sending) rather than a late collision occurring (after sending may or may not have ended). By having the collision occur at the NIC (local) and not on the wire (late) CSMA/CD implementation recover the situation by retransmitting later.

- The slot managers’ responsibility therefore is to get them the slots needed in time for flights to operate via communication with the respective slot coordinators. Not getting the needed slots in time may result in having to re-schedule flights, incurring operational costs that affect profitability and the passenger sentiment.

- Traffic Flow Management, slot coordination and allocation: slots are allocated as a function of the 'required time of arrival' to. ensure predictability eur-lex.europa.eu.

Some times for Ethernet slot time include:[2]

| Speed | Slot time[3] | Time Interval |

|---|---|---|

| 10 Mbit/s | 512 bit times | 51.2 microseconds |

| 100 Mbit/s | 512 bit times | 5.12 microseconds |

| 1 Gbit/s[4] | 4096 bit times | 4.096 microseconds |

| 2.5 Gbit/s onward | no half-duplex operation | |

See DIFS for information on 802.11x slot times.

References[edit]

- ^IEEE 802.3 4.2.3.2.3 Collision handling

- ^IEEE 802.3 4.4.2 MAC parameters

- ^Slot time is only applicable to half-duplex transmissions. Since slot time is the time required to wait for the medium to be free from transmissions, there is no time required to wait for full-duplex transmissions. 1 Gbit/s (in practice) and faster (by standard) are full duplex technologies, so slot time is not applicable here.

- ^theoretical, only full-duplex devices exist

Time slot booking offers forwarders and manufacturing companies a straightforward way to intelligently control their truck deliveries and pick-ups, while avoiding delays and long truck turnaround times at the plant due to delayed material or traffic jams. An intelligent time slot management system centrally manages the loading points and the necessary capacities, thus optimizing resource utilization not only at the plant level, but also down to each loading point for incoming and outgoing goods, if required.

Time Slot Management Wikipedia

For some time now, dynamic time slot management has been an issue in the logistics industry. For this purpose, the systems are linked to tracking systems that track the trucks in real time and therefore have precise information about the location of the vehicles and their arrival at the plant. A dynamic arrival time calculation automatically and precisely transmits the arrival time of the trucks to the ramp operator within a booked time slot. The theory behind it: If the truck does not arrive on time (or does), the new arrival time is transmitted directly to the system and the plant. Traffic jams that are difficult to predict or similar incidents that can quickly lead to delays are automatically taken into account. The aim of this approach is to have the flexibility to respond quickly to delays.

Time Slot Management Wiki

The problems

For time slot system operators and forwarders this sounds like a plausible solution- a very tempting one too. Continuous system synchronization offers reduced data maintenance and ensures that data is always up to date. However, this approach has its limitations. Peak times, such as midday retail, cannot be intercepted with this booking method. This is because dynamic time slots cannot regularize peak times for deliveries and pick-ups. Just because a time slot is dynamic doesn't mean it won’t fall right into a rush hour.

Even if all time slots were immediately adapted to the new Estimated Time of Arrival (ETA),it could still lead to traffic jams in front of the plant and at the loading points. The trucks can still arrive at the same time; for example, even if a forwarder is late, he can in fact no longer miss his time slot. Consequently, neither rush hours nor traffic jams are prevented.

The solution

However, this isn’t sufficient enough to solve the traffic problem. Adapting the time slots to the current situation alone does not allow efficient truck handling. This is only one aspect of a good and practical solution. It is also important to handle the arriving trucks on the basis of a set of rules and their priorities in real time, in order to ensure a transparent and fair handling process with the shortest possible waiting and throughput times- even in congested situations. Apart from transparency regarding the actual time of arrival, nothing else has been gained.

Time Slot Website

A rectification and reduction of waiting and throughput times is therefore only possible if the trucks are handled according to their order of priority. In addition to the time slot duration, this can be determined by a variety of other criteria, such as

- the material to be collected or delivered and the corresponding adherence to production and delivery dates

- contractual agreements with the forwarding agents (e.g. demurrage agreements),

- the importance of the customer or supplier behind the delivery,

- the number of loading points to be reached,

- the overall process, which in addition to loading can also include activities such as weighing or checklist procedures.

These few examples alone demonstrate how many influencing factors play a role in the truck handling of a commercial or industrial enterprise and how complex the loading and unloading process can be when trying to achieve the shortest possible waiting and handling times.

Intelligent solutions based on Artificial Intelligence (AI) and Operations Research (OR) methods are able to take into account the multitude of influencing factors according to their respective weighting offer real added value. They combine ETA information with knowledge- and rule-based AI and OR methods, thus enabling an efficient overall process in which not only the expected arrival time, but also supplementary parameters such as the ones described above are intelligently taken into account. Like an autopilot, these systems control the entire process in real time, so that manual intervention in loading area management is only necessary in exceptional cases.

Among other things, the basic principle of these intelligent control systems is thatreal time control only takes a truck into account after it arrives, and in the case of a delayed arrival, trucks are given a lower priority. It is important to note that this does not automatically mean that these trucks are continuously pushed to the end of the waiting loop, since intelligent control systems can dynamically re-integrate these trucks back into the overall process. As the waiting time increases, the priority of these trucks increases again, to guarantee an efficient overall process. When ETA calculations clearly indicate early on that a truck will not reach its booked time slot on time, the system takes the subsequent changes directly into account. For example, by bringing forward the time slot for another truck that has already arrived.

Closing Thoughts

There are various approaches to intelligently planning truck supply control and time slot management. Although the dynamic time slot booking approach maps the current situation of the trucks, it does not prevent peak times in the plant and therefore does not reduce waiting times. Since peak times are not avoided by dynamic time slots, they do not, in my opinion, offer a potential solution for traffic jams in and around the plant. It makes more sense to flexibly optimize the time slots according to the real conditions in the plant. Only then can long waiting times be brought to an end.

Time Slot Management

How are time slots booked in your company? What approach do you take to optimizing your truck supply control?